Official WeChat

Building Energy-Saving Materials

In 2 0 1 6 years, the construction of Yichang's production base started, and the development of Sinoma's energy-saving calcium silicate board industry kicked off.

After seven years of development, the company now has 5 calcium silicate board production bases. Three bases in Yichang, Qianjiang and Nigeria have been put into operation, and two bases in Chongqing and Chizhou are under construction (the first phase of Chongqing has been put into operation). The substrate production capacity is 35 million square meters, the decoration board production capacity is 40 million square meters, and the substrate production capacity under construction is 30 million square meters. At present, the energy-saving production scale of Sinoma ranks fourth in China, and after the Chongqing and Chizhou projects are all completed and put into operation, the static production scale ranks second in China.

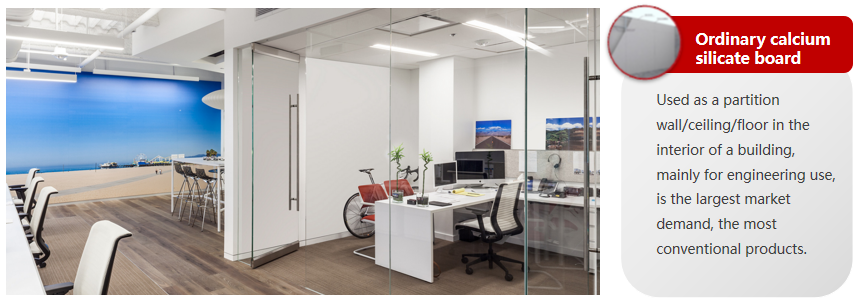

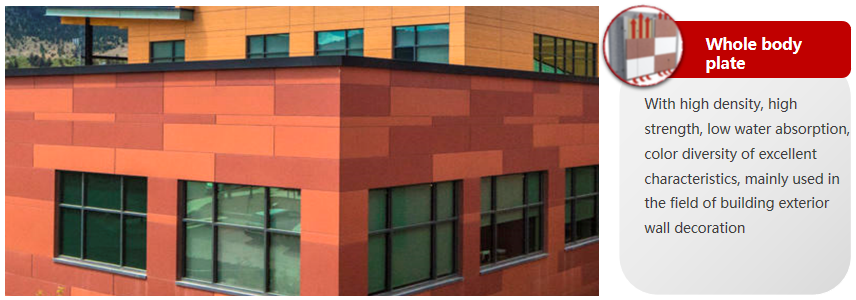

Sinoma Energy has always practiced the corporate mission of "creating a better world with materials", and has truly integrated "green" into the whole life cycle of calcium silicate boards. With its outstanding performance in green, energy saving, environmental protection and other aspects in the building materials industry, it has attracted great interest and widespread attention from customers at home and abroad as soon as it was listed. As a new type of green environmental protection building material, calcium silicate board not only has the functions of traditional building boards, but also has the advantages of superior fire resistance, moisture resistance and long service life. It is not only widely used in interior and exterior wall systems, ceiling and floor systems of industrial and commercial construction, but also in assembly interior repair, tunnel decoration and fire protection. clean spaces, interior walls, etc.